Though concepts like the greenhouse effect and global warming have been debated since the 19th century, public awareness of global warming really emerged in the past four decades.

Global warming is a real and measurable phenomenon, though it may not present itself in obvious ways. It’s a global trend, not a regional one. For instance, regional weather events may become more severe without demonstrating a clear local warming trend. It’s one of many reasons why global warming and its causes continue to be a source of debate and confusion among many.

The facts, however, are beyond dispute. Atmospheric carbon levels are on the rise, increasing steeply over the past century.

Most people agree that addressing climate change and pollution is important. What people can’t agree on is how. Carbon taxes and other pricing mechanisms are deeply unpopular, even though some pricing models are proven to reduce emissions. Think of the recent protests in France after they attempted to raise their carbon tax in 2019.

Experts tell us that there are two ways forward when addressing carbon emissions: pain or payment. Solutions either cause us pain—negatively impacting our standard of living through reduced consumption—or make us pay—causing everyday goods and services to cost significantly more.

Of course, nobody wants to do either. Measures to address carbon emissions on the demand side are unpopular, contentious, and as a result slow to come online. Supply side legislation receives pushback from industry and may result in rising costs for consumers.

When it comes to solving climate change, nobody wants to be the one to pay, or to feel the pain. We’re all waiting for our neighbours to make the first move. What if there’s another way forward? We believe that trenchless technology provides a painless way to reduce the carbon footprint of one of the world’s most polluting industries.

The building and construction sector accounts for as much as 21% of global carbon emissions. Even modest improvements in this sector can make a significant impact on the rate of climate change.

Many factors contribute to the high carbon cost of construction. Manufacture of building materials, operation of diesel-powered heavy equipment, and other energy requirements like heat and lighting for outdoor work sites all contribute. Excavation is a particularly intense source of emissions. The process itself can release otherwise sequestered greenhouse gases from the earth. Earth is heavy; moving it with heavy equipment takes a significant amount of energy in the form of diesel fuel.

Our research suggests that trenchless technology can offer carbon savings of over 90% versus conventional excavation for utility line projects. By its very nature, trenchless technology removes the most carbon intensive process from utility installation, management, and repair.

In 2017, we helped the City of New Westminster receive a carbon credit for its trenchless repair program—the first city in the world to receive a credit for such a program. We believe that broad implementation of trenchless technology can make a measurable impact on construction industry emissions while maintaining cost parity with conventional construction methods.

Conventional excavation projects are carbon intensive. Let’s start by considering fuel usage. A piece of excavating equipment can burn about one hundred litres of diesel fuel in a day of continuous operation. This is equivalent to the energy used by an average household for a month. A particularly efficient electrical vehicle could drive from coast to coast across the United States using the same amount of energy.

There are many other dimensions that contribute to the carbon footprint of excavation work, from disruption of sequestered greenhouse gases in the excavated soil to the carbon costs of repairing and replacing road surfaces after the work is complete.

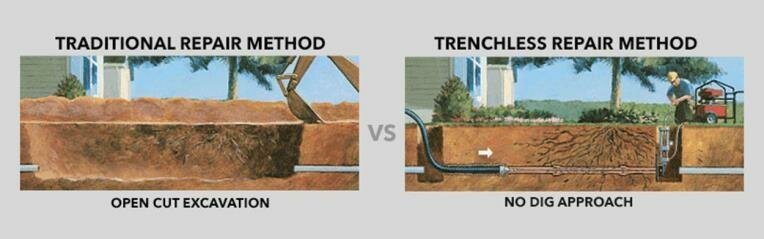

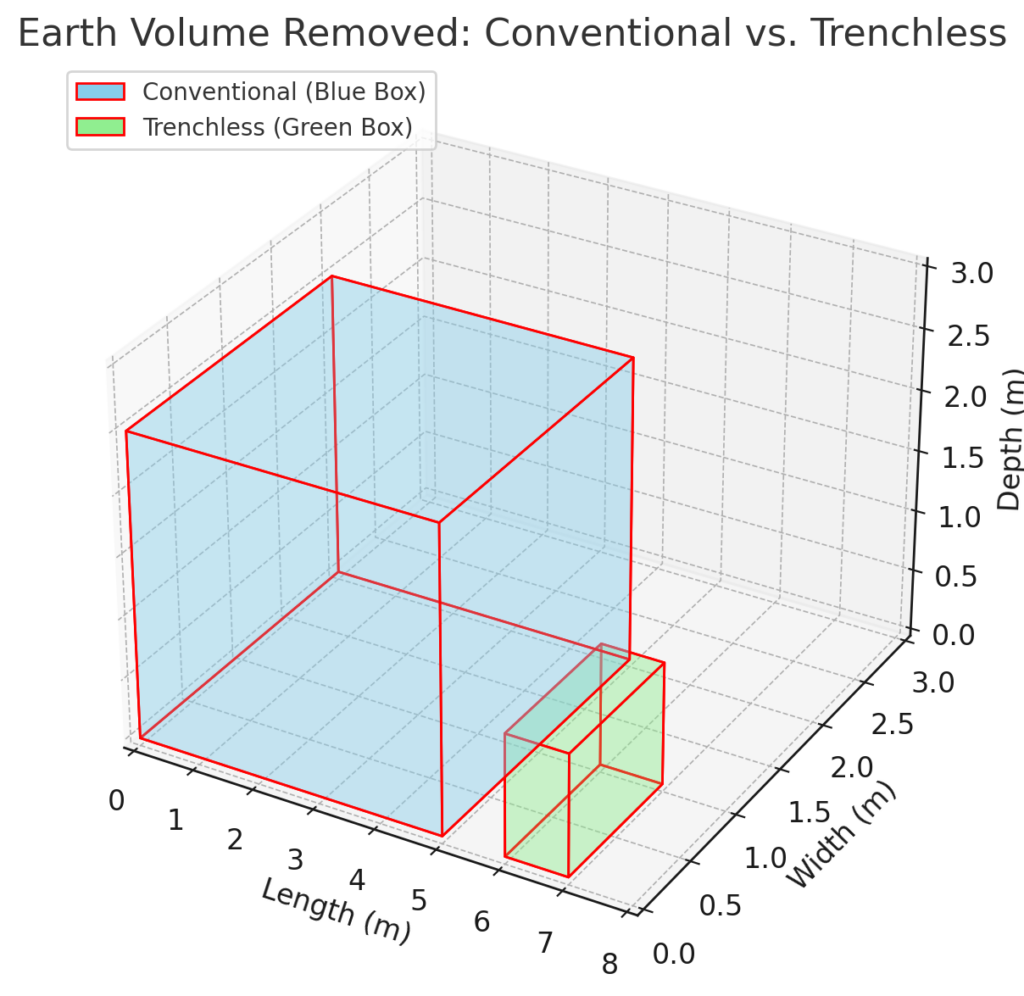

Trenchless technology helps address excavation impacts by simply digging less. Consider a sewer line replacement for a 200mm pipe. A conventional approach would require digging a trench about 1m wide and 2.5m deep, running the length of the pipe to be replaced. That’s 2.5 cubic meters of earth to move per meter of pipe to be replaced.

The pipe itself has a volume of just 0.031 cubic meters, meaning that conventional excavation moves eighty units of excess material to gain access to the pipe.

A trenchless solution can sometimes avoid all excavation. In situations where an access point must be cut and excavated, trenchless technology might require digging up a single cubic meter of earth or less.

By minimizing digging, trenchless technology reduces the impact of construction work on motorists, resulting in less idling and fewer detours.

The reduced carbon impact of trenchless technology isn’t just a hypothetical. Though accounting for every carbon-generating factor in a construction project is difficult, our carbon emissions calculator provides a realistic model for potential greenhouse gas reduction by choosing trenchless technology. You can download the calculator in Excel format here.

In many cases, trenchless solutions compete on cost and timeline versus conventional construction. At the same time, trenchless technology offers a low-carbon option for utility management. It’s less disruptive to commuters and communities. It’s quieter and safer.

Where most potential solutions to climate change come with a hefty cost, adoption of trenchless technology doesn’t. We hope that as more and more communities become aware of the myriad benefits of going trenchless, we can be an integral part of the climate solution.

An alternate tendering process where the contract is awarded to one entity which comprises both engineering and contracting.

Because PW Trenchless Construction offers such innovative solutions for underground utilities, it is often beneficial for the owner to request solutions based on a performance specification. This allows PW Trenchess to offer unique solutions while working with equally innovative engineering companies. Learn more about design - build here!

More InfoNew installation methodologies include HDD & traditional open cut Learn more about new installation here!

More InfoIn this day & age of pipe systems reaching the end of their projected lifespan, pipe replacement and pipe rehabilitation have become major fields of engineering.

PW Trenchless Construction provides viable options such as pipe bursting, loose fit lining and internal pipe re-construction whether partial & fully circumferential. Learn more about pipe replacement & rehabilitation here!

More InfoThe aging culverts under roads and highways in many case have reached the end of their engineered life-span. We consider the rehabilitation or replacement of these culverts to be vital to our built environment.

PW Trenchless has been a pioneer in working with MOTH, railway companies and municipalities in developing rehabilitation methodologies for the hundreds of thousands of culverts that currently exist in BC. We have offered solutions in both procurement and construction from design-build to sliplining, invert rehabilitation and full circumferential relining. Learn more about culvert rehabilitation here!

More InfoOften pipe failure can be concentrated to one section, for various reason, leaving the rest of the pipe in good condition. The repair of these localized failures are know as external point repairs (EPR's).

EPR's demonstrate PW's ability to work as both a trenchless and civil contractor, completing EPR contracts using our civil contracting skills and assisting other pure trenchless contractors who only have the capacity to work in an existing pipe. Learn more about point repairs here!

More InfoPipe upsizing is the fundamental concept of pipe bursting.

The vast majority of pipes are less than or equal to 200mm in diameter, but with today's densification practices of urban design, there is a major demand to increase current capacity to handle extra flow. Pipe bursting provides the ideal solution to this issue, particularly in an urban setting. Learn more about pipe upsizing here!

More InfoHorizontal Directional Drilling is a low impact Trenchless construction service where pipe is installed in a shallow arc along a bore path which has been created by a drilling rig. Often the terms Horizontal Directional Drilling (HDD) and Directional Boring are used interchangeably, but in our industry we use the word “boring” when we utilize smaller sized drilling rigs with small diameters for short crossings in the hundreds of feet, and we use the word “drilling” when we utilize larger rigs with large diameters for long crossings in the thousands of feet. Learn more about horizontal directional drilling here!

More InfoPrimus Line® is a flexible sliplining solution for the trenchless rehabilitation of pressure pipes. The system consists of a flexible Kevlar® reinforced liner and specially developed end fittings. Primus Line® is not bonded to the host pipe and is self-supporting. An annulus remains between Primus Line® and the host pipe.

Developed by experienced engineers, the system is suitable for different media as well as various application needs and has already proven itself in numerous projects.Learn more about primus lining here!

More Info

When you join PWT, you become part of a community of people who are engaged in the most innovative practices in the Trenchless Industry. We have been instrumental in setting up a scientific method for cities to gain carbon offsets/credits from their use of trenchless construction. This system has been reviewed by the BC Government and has been approved as of December 2018. We expect to see it in common use shortly.

Subscribe to our newsletter for cutting-edge industry updates, expert knowledge, and exclusive content.