Pw Trenchless Victoria 2023

During 2023 PW Trenchless Construction Ltd. re-lined three sections of existing sewer mains in Victoria, with GRP pipe (Glass Reinforeced Plastic). Under Oxford Street at Chester Street there was a 1000x1600mm GRP pipe installed via lining for approximately 43 meters, heading West from the intersection.

A section of Cook Street from Packington Street to Fairfield Road was also re-lined with GRP Pipe for a distance of approx. 93 metres including two manholes were rehabilitated.

Through an easement from Joseph Street to Eberts Street, 126.5 meters of pipe was rehabilitated via lining with GRP Pipe.

2022 PortMoody September 12

On September 12 , 2022, Insituform started to line the existing sanitary sewer lines that go through the Old Orchard Park. Insituform® CIPP is a cured in place pipe liner that is installed via air pressure. This is not a new experimental process and has been used for 5 decades and the life of 25,000 miles of pipe worldwide has been extended via the Insituform® CIPP.

The process had started months earlier with PW Trenchless Construction installing a sewer by-pass system to ensure the forcemain sewer main would be dry for the lining process and any flows of the sewer would be maintained while the process was proceeding. Entrance and exit pits were excavated and sored and fenced off to ensure the safety of the public on these well used trails. Although the first sewers to be relined were gravity mains, and the bypass system was not needed for the gravity lines, the lining process did not start till all the bypass system was in place, and all excavations completed.

The starting date for the Edmonton based Insituform crew, was a dry sunny day that had followed an unusually long dry period for the Lower mainland area of British Columbia. The crew showed up and the first process, was the obligatory wheel washing process to ensure no contamination into the parks eco-system. The Insituform crew did a camera inspection of the line, and they could send up a cleaning wand if needed.

Once inspected, the truck which controls the lining system was put in place by the entry point at an existing manhole. At both the entry point manhole and the exit point manhole, a pipe testing plug was installed into the pipes entering the manhole that were not part of the lining process that day. This ensure no stray debris enter the “Host” pipe, the pipe that is to be lined.

The truck holding the liner is set up in place and the new liner has been “wetted” and needs to be kept cool with bags of ice surrounding the pipe supply. The liner is a Poly sleeve that has a felt inner membrane that is impregnated with a fiberglass type resin and pulled through a series of rollers at a specific height to ensure the whole membrane has an equal and proper amount of resin throughout the length of the liner.

A pipe liner inverter is set up over the entrance manhole and the liner is fed trough the inverter and the end is inverted, and held in place with steel bands. High pressure air is inverted into the plenum of the inverter to force the liner downwards into the entrance manhole and it is redirected by a wedge in the invert of the manhole that directs the liner towards the pipe to be lined.

As the air continues to be forced into the inverter, a liquid lubricant is applied to the “pipe Inverter” to allow the new liner to be installed with the minimum of friction and no damage to the liner. While the lubricant was added and poly tub was placed on the ground to make sure if any liquid dripped out it would be captured and not allowed to impregnate the ground of the park.

As the liner is inverted into the host pipe, the resin impregnated felt inner part of the liner inverted and is forced against the inside of the host pipe. It is not dragged along but rather is installed from the inside out and goes all the way to the exit manhole where it is guided out of the manhole via wood wedges that force it up and out of the manhole.

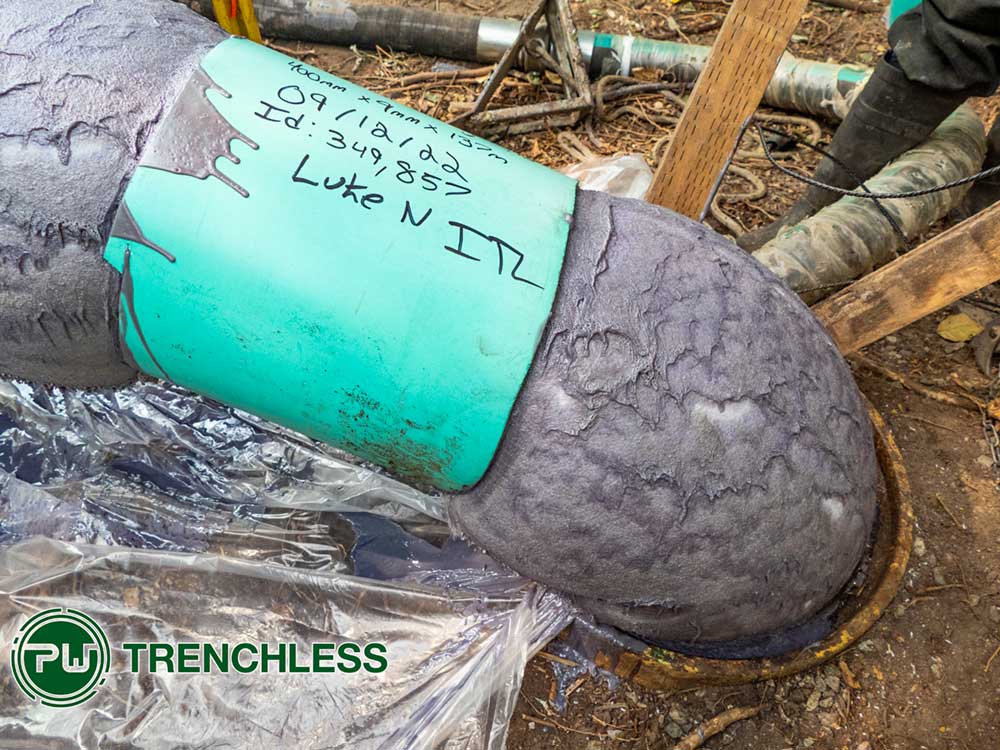

Once the liner was installed throughout the host pipe, a sleeve made of PVC pipe, the same diameter of the host pipe is placed around the excess liner on the ground out side of the exit manhole. This is marked with the date and batch number of both the liner material and the resin to provide a test sample of the liner.

The end of the installed liner is tied off and a small hole is drilled into the liner and a steel manifold pipe is inserted into the hole as a port to let the pressurised air escape. This steel pipe has a pressure guage along with a valve to allow the pressure to build up and keep a constant pressure to keep the liner mated closely with the host pipe. Once pressurized, steam is introduced to start the curing process. Temperature probes are carefully monitored to ensure critically important constant and even curing times and temperatures.

After a predetermined time, set by the length and diameters of the project, with a considerable safety margin, the steam is replaced by air and the pipe is cooled and then the pressure removed. The ends of the pipe are cut off and removed in sections to allow access to the manholes. After accessing the manholes the ends of the liners are carefully cut to correct shape of the host pipe as it enters the manhole.

Cleanup and removing of the excess is fast and careful, with all necessary means used to ensure no damage to the surrounding area or manholes.

2022 Port Moody Sept 28

On September 28 , 2022, Insituform started to line the existing sanitary sewer lines that go through the Old Orchard Park. Insituform® CIPP is a cured in place pipe liner that is installed by pulling through the existing, or “Host” pipe. The sanitary sections of the sewer are installed using the iPlus® Glass process. According to the Instituform website, the iPlus® Glass liner is reinforced with glass fiber and can be cured using an ultraviolet (UV) method. This trenchless CIPP solution is a jointless, seamless, pipe-within-a-pipe. It can be used to rehabilitate pipes ranging in diameter from 6 to 48 inches (150mm to 1200mm).

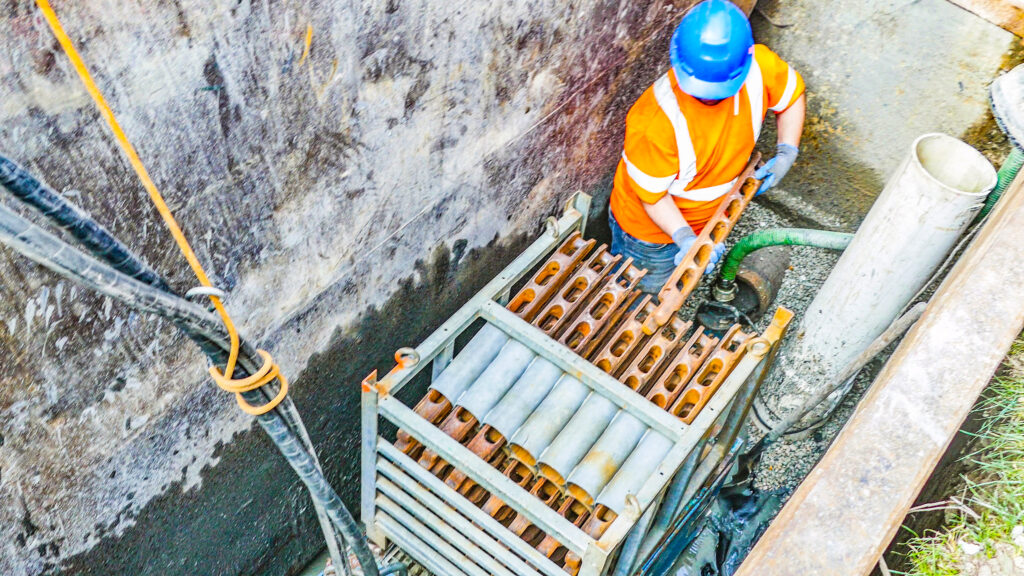

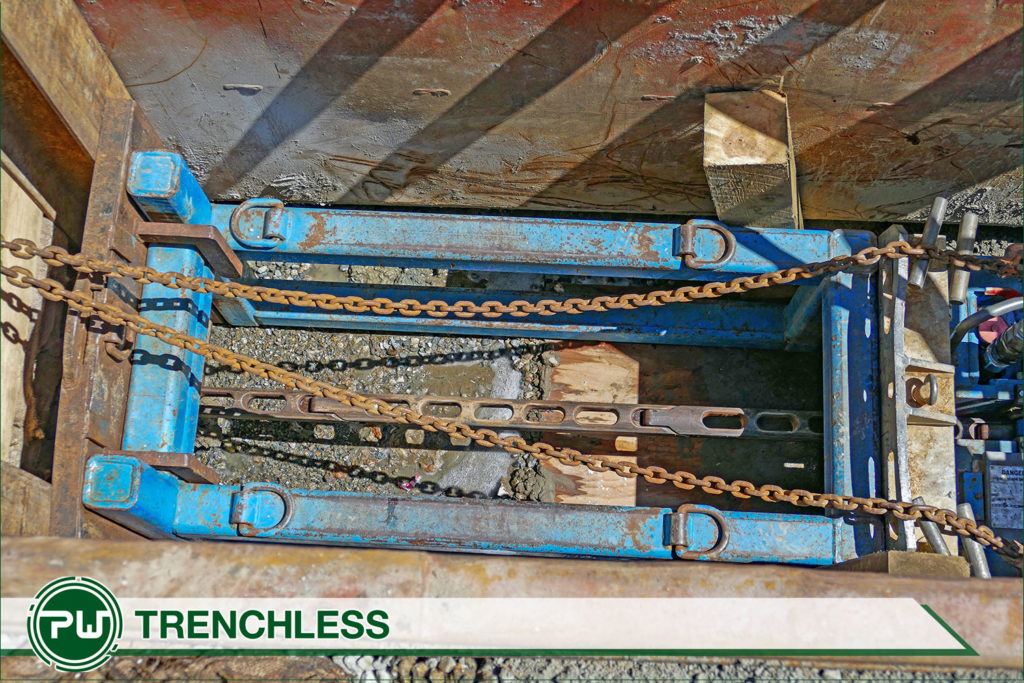

Unlike the CIPP method used on the sanitary gravity sewers in the park earlier in the month, there is quite a bit of preparation need to complete these projects. Along with the bypass pumps and piping installed for the sanitary forced sewers. Entrance and exit pits need to be excavated and shored with trench shoring cages. The sanitary sewer is a forced main and as such does not have open manholes to install liners through. The entrance and exit pits are paced at predetermined lengths of the pipe main, and are sensitive of the surrounding trees of the park.

The pits were all excavated and shored by the crews of PW Trenchless Construction during the months prior to the relining operations. The ends of the pipe to be lined are cut perfectly square on the day of the burst with a strong section of C-900 Waterman PVC pipe attached with a flexible coupling. This will allow for ratchet straps to hold the liner in place without fear of cracking the host pipe.

The iPlus® Glass installation process is much different than the Insituform® CIPP installation used on the Port Moody Gravity Sewer mains that PW and Instituform installed early on in September. While the camera is being sent up the host pipe for it’s initial inspection the morning of the lining, a plastic liner is attached to the camera rig and pulled back trough the host pipe, along with a pull rope for installing the tugger cable. This plastic liner aids in reducing friction when pulling the liner through the host pipe and reduces the chance of damaging either.

To help keep the liner in place, a portion of the liner is sent up the other part of the Host pipe that will not be used that day, on the other side of the excavated pit. A sewer test plug is inserted and inflated and does a good job keeping the liner from slipping along with the liner as it is installed. The tugger cable is pulled through and attached to the liner, for pull back. A plywood deck is placed on an angle and the crate with the Liner is placed on top and the end of the liner is attached to the end of the cable and the liner is installed into the host pipe.

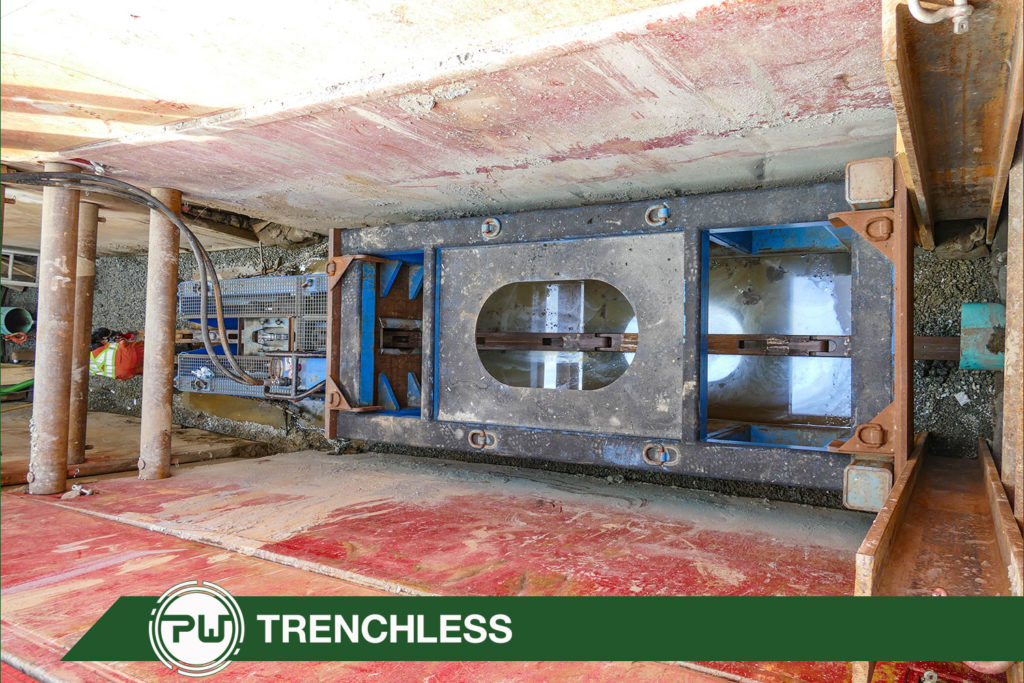

Once the liner is installed, at the far end, the “exit pit” where the tugger is located, a steel flange is attached and held in place with ratcheting straps. This allows for steam, air and the control cables utilized for the inflation and curing of the pipe liner to be inserted. At this point, where the liner was inserted, the “Entrance Pit”, the light apparatus is installed and a similar steel flange is inserted and held in place with ratcheting straps. Part of the plastic liner is also pulled over the end held in place with tape and straps. The lighting apparatus is installed in to the bag and the end is tied off. Air is inserted from the far end to inflate the liner and the clear plastic bag around the entrance pit end.

Once the liner is partial inflated, a slit is cut in the plastic and control and power cords are attached to the lighting apparatus. The lights are then placed inside the liner and the end is seal with a flange that allows for the control and power cords to go through the flange while the full pressure is applied. The lights are pulled all the way to the exit pit and the air pressure and heat are applied until the proper settings are reached. The lighting rig has numerous lights that cure the fiberglass resin impregnated liner until it is as durable as PVC pipe.

After a number of hours, almost 6 hours for the September 28, 2022 lining job, the pipe is fully set up and ready to be used. The project in the Port Moody Old Orchard park had a number of sections in a row to be lined. Over the next few weeks, all the liners were installed, and uncharacteristically for the lower mainland area, the job was completed prior to the rains starting to fall.

The City of Richmond has commenced a 5-10 year project to replace and improve the water mains, sewers and roadways in the Burkeville area of Richmond near the Vancouver International Airport. This area has been prone to flooding so a newly expanded drainage system over and above the existing open ditches is needed to reduce the flood risk in the future.

Phase 1 and 2 have been completed and in Phase 3, along with PW Trenchless Pipe Bursting, all water mains will be replaced, trees and hedge trimmed or removed, installation of a new drainage system, and repaving of the road and installing a new gravel shoulder to roadways.

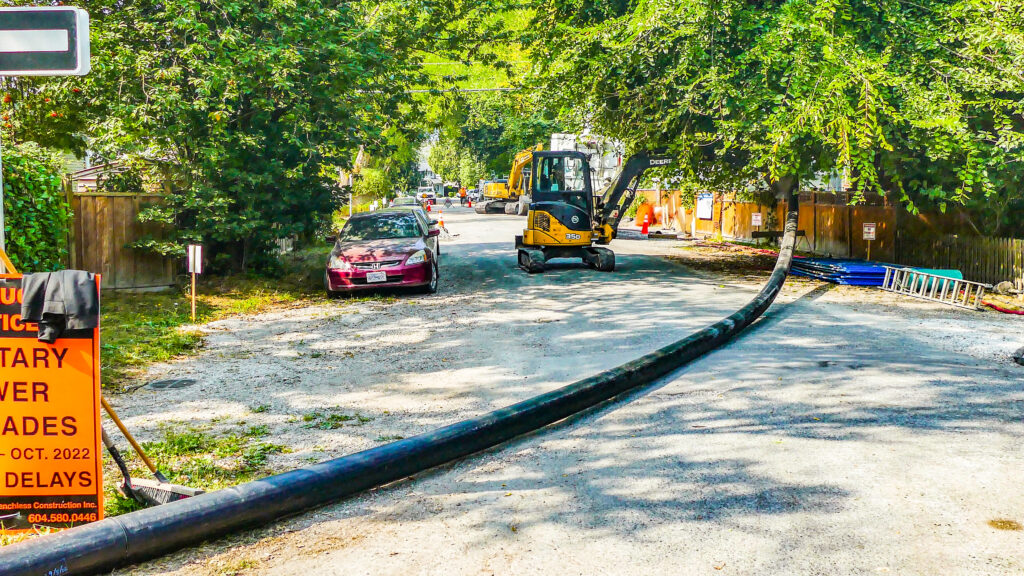

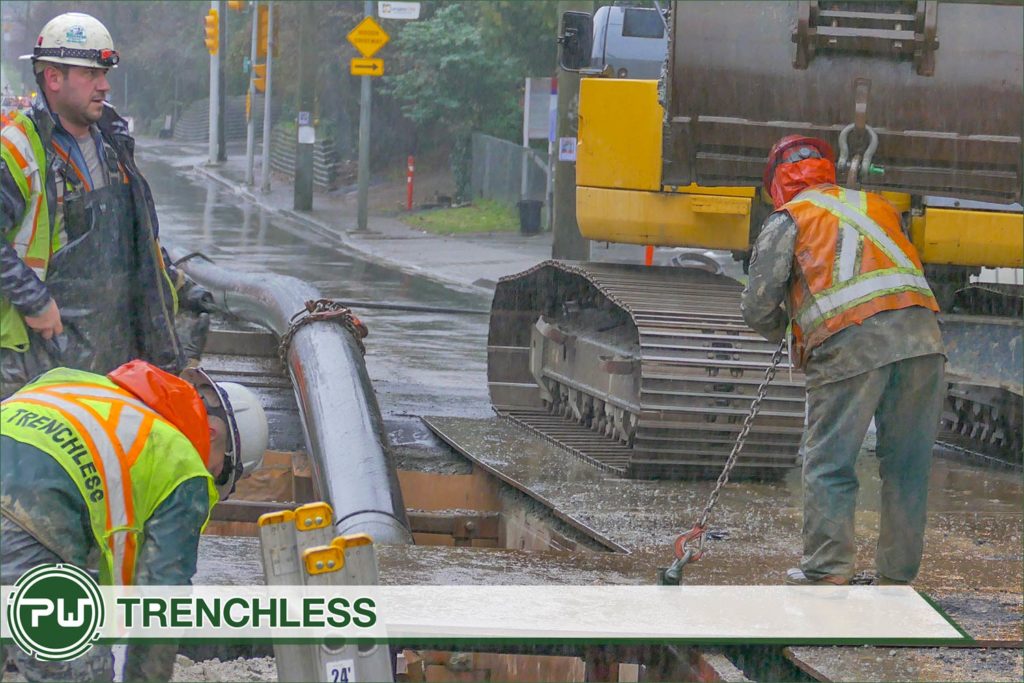

From September 6th 2022 to October 28, 2022 PW Trenchless replaced 265m of existing sanitary mains via pipe bursting and was lucky to be able to do the work at the tail end of an extremely dry period of weather for the Lower Mainland. The water table is typically extremely high during normal times in Richmond, so the dry weather was a plus for this project.

The Burkeville area of Richmond is one area of Richmond that still has ditches, and when the crew was initially looking at the project in the Spring, the ditches were full of water.

The City had installed a sign for the residents to see the scope of the project and PW Trenchless’ part of phase 3 included:

-Clearing and tree removal at entrance and exit pits locations.

-Trimming trees that may interfere with excavation and mobilization.

-Excavations of entrance and exit pits.

-The dewatering of excavations if required along with the treatment of discharge water.

-Fusing of HDPE pipe on site within approved laydown area.

-Trenchless pipe bursting of 130m of existing 200mm (8″)AC pipes with 200mm HDPE.

-Trenchless pipe bursting of 130m of existing 250mm (10″)AC pipes with 250mm HDPE.

-Restoration of excavated areas.

On September 13th of 2022, after the long dry spell mentioned above, PW Trenchless Construction did two of the 6 bursts that are part of this project. The entrance and exit pits had been dug prior to the day of the burst, and the depth was not too deep. The pits were dry enough to just need a couple of smaller pumps to handle the ground water and De-watering was not needed. A rare occurrence for Richmond.

The tugging apparatus was installed and the pulling rods were inserted through two runs of pipe. Starting at 11a.m. And arrived in the entrance pit an hour later. The rods went right through one of the existing manholes near mid point of the two runs.

The first section of HDPE pipe had been staged in a park area near the burst and the road needed to be temporarily closed to traffic. Traffic for the area is extremely light as there are not very many homes and they were able to drive the other direction to access the subdivision.

Once the pipe was staged, it already had the pulling head attached, it was connected to the pulling rods and the burst commenced at 12:24pm and was finished at 12:52p.m.

The head was removed and the new section of pipe was staged alongside the roadway and the bursting head was attached. A bit of Hydro excavation was done around the gas main for safety and the second burst started at 2:20pm and finished at 2:37p.m. The head was removed and the two sections of pipe were connected to the existing pipe at one end and grouted into the manholes where needed.

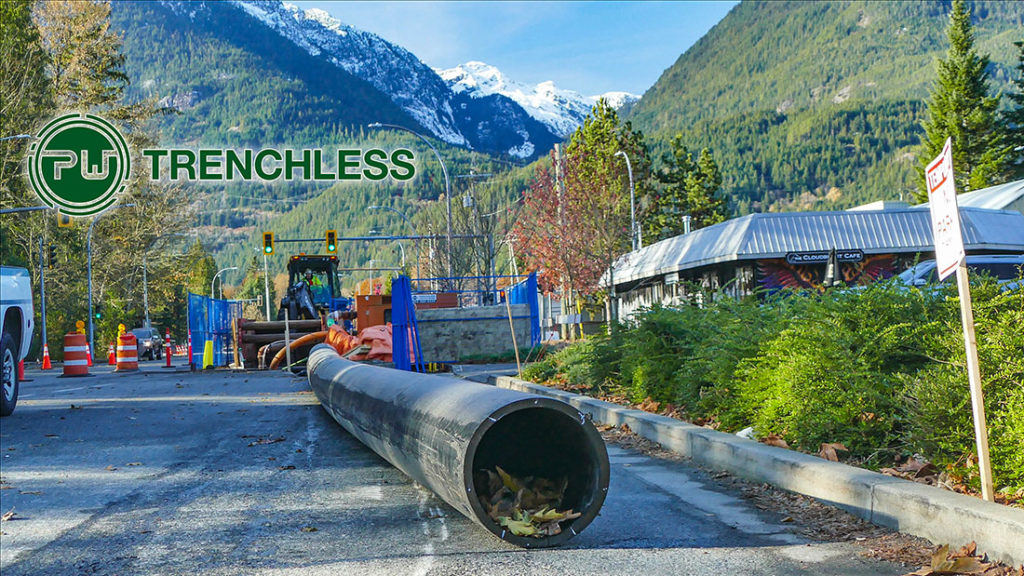

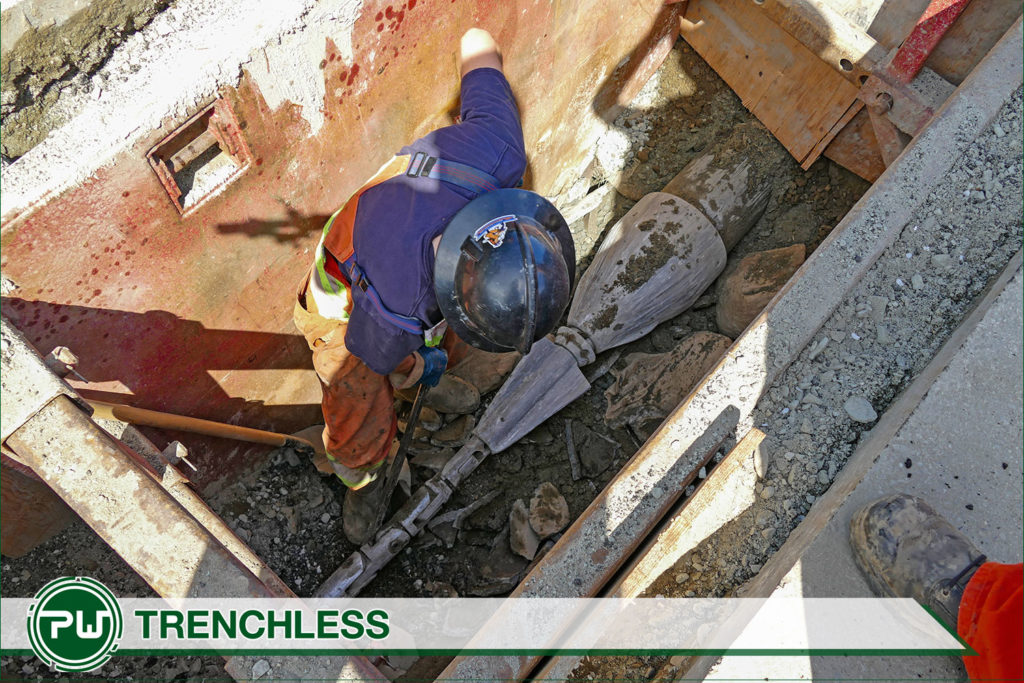

The crew at PW Trenchless were up in Squamish to replace a sewer main under highway 99 via Pipe Bursting. On November 15, 2022, the first burst of 135 metres took place along Mamquam Road towards Highway 99. The exit pit was dug close to the intersection of Mamquam Road and Highway 99.

The site was not suitable for using a pair of trench shoring cages so the removal of the large pipe bursting head was a bit more complicated and required some extra excavation once the burst was completed. The burst went smoothly and the 135m of pipe were inserted via Pipe Bursting in roughly 3.5 hours.

Of course there was quite a bit of set up before the burst was started. For this project, it was decided to excavate around two manholes and jackhammer out the benching and channels of the base of the manholes. This allowed the burst to continue through the two manholes unimpeded, allowing for just one launch of the bursting tool for this 135 metre run. The two manholes had trench shoring cages supporting the excavation as well as a few spots where the existing infrastructure was excavated to make sure the bursting head could pass without causing any problems.

The entrance pit was 4 metres deep so the large diameter 450mm HDPE pipe had to have a long sloped entrance ramp excavated to allow the pipe to enter the host pipe without any grade, allowing the grade of the host pipe to be unaltered.

The HDPE pipe was fused together and there was a large lay down area on the side of the road by the golf course that was not in any vehicles or pedestrians way. There was a bypass pump system put in place and various additional pumps were set up to ensure the excavations were kept dry for the duration of the burst.

On the day prior to the burst, the pulling apparatus was put in place and the pulling rods were inserted into the Host Pipe. The pulling cone was installed on the lead end of the HDPE pipe. The morning of the burst it was moved across the road and put in alignment with the host pipe.

The pumps looked after any existing ground water in the excavations, but luckily it was a dry sunny day. The weather was a bit cold and once the Replacement pipe was staged into the entrance pit it was discovered that the swivel that connects the Bursting head to the pull back rods had a small amount of ice in the cavity. The swivel was hung above the exhaust of one of the nearby generators that were powering the bypass pump and the ice was removed.

Once the head, swivel and pull back rods were attached, the crew took a well deserved coffee break and the burst commenced before 11a.m. The crew was diligent watching the inspection pits to make sure the bursting head and pipe went under the existing infrastructure without damaging any existing pipes.

The site was wide and traffic was only stopped a few times while excavators needed to be moved to align the pull back rods when the swivel and head were attached and then to move a generator to all the vacuum truck better access to remove debris from one of the pits.

The length and depth of this sewer main made it a perfect candidate for pipe bursting, and saved approximately 560 Tonnes of material or 40 truck loads of material from being excavated out of a trench for open cut replacement of this pipe. Unfortunately the section of pipe under the Sea to Sky highway has had some repairs in the past so, pipe bursting that section is still being looked at as a possibility.

This was a 120 metre burst and was the longest of the three burst in this project for the Township of Langley. Working on 200th Street has it’s challenges but the work went smoothly and traffic control was important to the completion of the job. The pulling rig has the capabilities of pulling up to 430,000 lbs or 215 tons. The pressures for this pull were never very high. The rig only came with 123 m of pulling rods so the entrance pit had to be elongated to allow the pulling head to be inserted close enough to the pulling rods.

City of Langley

200th and 50th

Sewer upgrade from 8″ 200mm to 16″ 450mm

Numerous runs and a few open cut section to replace over 300 m of pipe and manholes. The section are over 4 m deep and 200th is an extremely bust thoroughfare.

March 29, 2021

The city of White Rock had a sewer main that needed replacement just up from the west end of the beach with the exit pit was just west of the intersection of West Beach Avenue and Anderson Street. The run was west on West Beach Avenue and many house were located along the street making for a tight situation for the lay down area for the fuse sections of HDPE pipe. The best situation was to fuse the sections into two runs with a final fuse of the section done just prior to the burst.

8:50 a.m. The rods were inserted into the host pipe and sent up to the exit pit.

10:14 a.m. the rods entered the entrance pit. While the rods were being installed, the steel plates that had been securing each of the service laterals were removed. The two sections of the HDPE pipe were moved into place and the pulling head was installed onto the East end of the HDPE pipe. The pipe was then staged at the entrance pit waiting to be attached to the pulling rods.

10:21 a.m. the Pulling head was attached to the rods.

10:24 a.m. The new HDPE pipe enters the host pipe

10:33 a.m. The pulling head enters the first of the Service lateral connection pits

10:35 a.m. The pulling head enters the first of the gas service connection inspection pits. No problems with excess soil. No contact was made with the gas service line.

10:40 a.m. The pulling head enters the second of the gas service connection inspection pits. No problems with excess soil. No contact was made with the gas service line.

10:49 a.m. The two sections of HDPE pipe are fused together without interrupting the pipeburst in progress. The fusion machine is one wheels and can easily roll with the pipe being inserted.

11:20 a.m. a gas service had been previously excavated for observation while the pulling head was going past the gas service. A large amount of the material had to be dug by hand to clear the soil that had been pushed into the excavation by the pulling head. The Gas service was left intact.

11:31 a.m. A Steel Robar type repair couple had to be cut away from the bursting head. This was only done to ensure clearance for upcoming gas and water service connections.

1:07 p.m. Another Steel Robar type repair couple had to be cut away from the bursting head as it came into and service lateral connection pit.

1:40 p.m. The pulling head reached the Exit pit (Pulling pit) Approximately 140m of pipe installed in 3 hours and twenty minutes.

10 city blocks of sewer were replaced on a steep street in the City of West Vancouver in late spring of 2019. Starting at the Clive Avenue and going up the hill to Mathers, the complete sewer was replaced.

Special challenges on this project were the numerous schools and parks within the project’s area. Traffic was managed but many residents learned quickly to drive over to either 12th or 14th Street. Road plates were used over the excavations when school was letting in and out for the safety of the children walking to school.

Although the host pipe was not deep it was on a severe grade and bursting downhill is easier on the equipment. To minimise the amount of exit pits, a few times two burst were completed using the same exit pit by sending the pulling rods straight through an existing manhole and doubling up the length of the run for the rods. The pipe was pulled through the higher Host pipe and then another section of pipe was attached at the manhole midway and inserted into a second entrance pit.

This was the final part of the contract that was started in 2017 with 5 of 8 Sections completed by PW Trenchless starting in 2015. This project was also the first time PW Trenchless had tried to replace a 200mm pipe with 450mm pipe, an upsize of 2.5 Times the flow for the pipe. This was certainly in the experimental stages for this type of upsizing and the pipe was fairly new PVC which although still having many serviceable years left, the increase of population density was overwhelming the pipe.

A special cutter was used to split the PVC pipe to aid the burst. A bentonite lubricant was also used to lessen the friction of the ground surrounding the pipe and was pumped into the interior of the new HDPE pipe and inserted into the void right behind the bursting head. The head was also comprised of three piece including two various sizes to compress the surrounding material as well as the cutter.

The first sections were burst through Kanaka Creek park and PW Trenchless was very concerned with environmental conditions including high water levels and the presence of the public visiting the park. The park was not closed at any time due to the work performed by PW Trenchless.

An alternate tendering process where the contract is awarded to one entity which comprises both engineering and contracting.

Because PW Trenchless Construction offers such innovative solutions for underground utilities, it is often beneficial for the owner to request solutions based on a performance specification. This allows PW Trenchess to offer unique solutions while working with equally innovative engineering companies.

Learn MoreIn this day & age of pipe systems reaching the end of their projected lifespan, pipe replacement and pipe rehabilitation have become major fields of engineering.

PW Trenchless Construction provides viable options such as pipe bursting, loose fit lining and internal pipe re-construction whether partial & fully circumferential.

Learn MoreThe aging culverts under roads and highways in many case have reached the end of their engineered life-span. We consider the rehabilitation or replacement of these culverts to be vital to our built environment.

PW Trenchless has been a pioneer in working with MOTH, railway companies and municipalities in developing rehabilitation methodologies for the hundreds of thousands of culverts that currently exist in BC. We have offered solutions in both procurement and construction from design-build to sliplining, invert rehabilitation and full circumferential relining.

Learn MoreOften pipe failure can be concentrated to one section, for various reason, leaving the rest of the pipe in good condition. The repair of these localized failures are know as external point repairs (EPR's).

EPR's demonstrate PW's ability to work as both a trenchless and civil contractor, completing EPR contracts using our civil contracting skills and assisting other pure trenchless contractors who only have the capacity to work in an existing pipe.

Learn MorePipe upsizing is the fundamental concept of pipe bursting.

The vast majority of pipes are less than or equal to 200mm in diameter, but with today's densification practices of urban design, there is a major demand to increase current capacity to handle extra flow. Pipe bursting provides the ideal solution to this issue, particularly in an urban setting .

Learn MoreHorizontal Directional Drilling is a low impact Trenchless construction service where pipe is installed in a shallow arc along a bore path which has been created by a drilling rig. Often the terms Horizontal Directional Drilling (HDD) and Directional Boring are used interchangeably, but in our industry we use the word “boring” when we utilize smaller sized drilling rigs with small diameters for short crossings in the hundreds of feet, and we use the word “drilling” when we utilize larger rigs with large diameters for long crossings in the thousands of feet.

Learn More

When you join PWT, you become part of a community of people who are engaged in the most innovative practices in the Trenchless Industry. We have been instrumental in setting up a scientific method for cities to gain carbon offsets/credits from their use of trenchless construction. This system has been reviewed by the BC Government and has been approved as of December 2018. We expect to see it in common use shortly.

Subscribe to our newsletter for cutting-edge industry updates, expert knowledge, and exclusive content.