Maple Ridge Alley

In the early part of 2019 PW Trenchless replaced a sewer for the city of Maple Ridge in a narrow laneway parallel to Lougheed highway. The project was complicated by the tight setback of buildings that in some case were right up to the property line.

The depth of the existing sewer ruled out open cut construction as an option and the entrance exit pit in the center of the project was extremely complicated to excavate. A soils Engineer was brought in to document and access the ground conditions to ensure the safety of the crew and the success of the pit.

Liberal use of trench shoring cages by Direct Equipment West Limited allowed for the pits to maintain open for the duration of the project even if heavy rains came. Staging of the pipe was done within the footprint of the job as no driveways or entrances were on the south perimeter of the job.

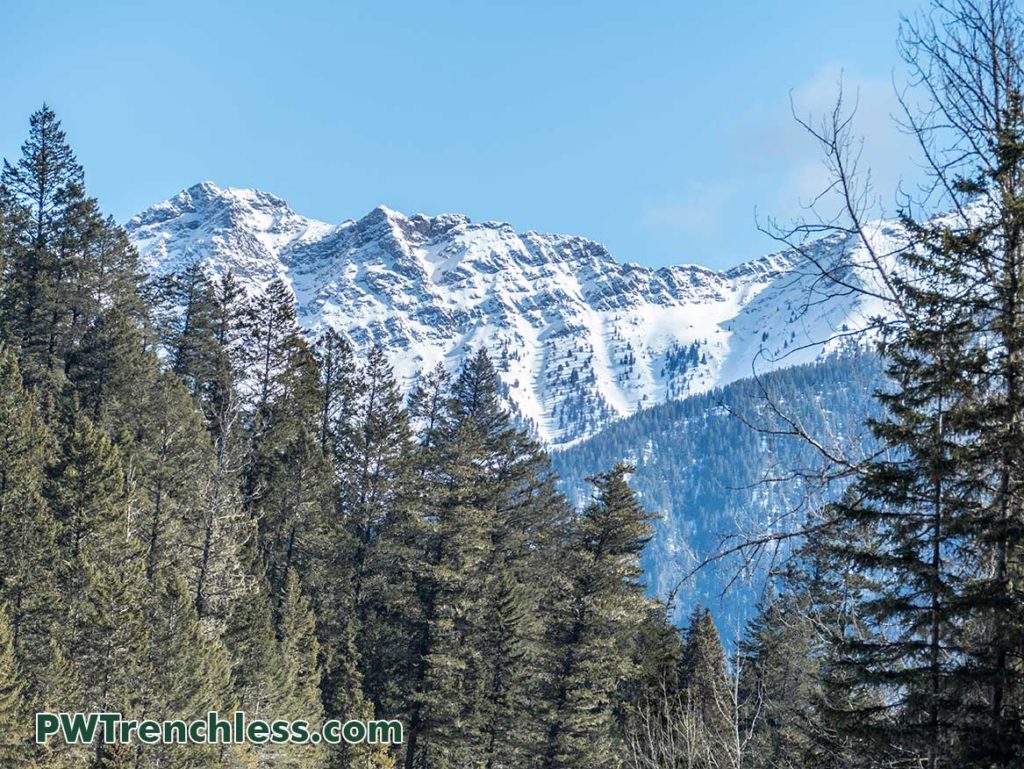

The fall and winter of 2019/2020 was again a time for PW Trenchless to completely measure and prepare 2 sections of pipe within the Radium Hot Springs park area for the installation of Glass Reinforced Plastic pipes inside two Culverts in Radium Hot Springs just North of the Hot Pools. Both had roadways on top of them and the crew had to install the pipe sections in the winter when the flows of the Sinclair Creek are at the lowest.

The longer of the two sections was just North of the Radium Hot Springs pools and the other section was a few kilometres up the Banff-Windermere Highway. The project uses Glass Reinforced Plastic (GRP), supplied by Chaneline International. GRP is a precast segmental liner which allows for, after a meticulous measuring process, each section of GRP to be hand formed and specifically designed for a particular location in the host pipe before being shipped to site.

This meticulous measuring was accomplished by a team of PW Trenchless technicians who spent many days inside of the host pipe made of deteriorated Corrugated Steel. When the pipe was delivered to the site, PW Trenchless Construction had already set up the By-pass pump systems and cleaned out the host pipe to make way for the new sections of pipe.

The pipes were installed on steel channels welded to the bottom sides of the Host pipe and once all the pipes were installed, concrete was pumped into the void between the host pipe and the outside of the new Glass Reinforced Plastic. The outside of the Glass Reinforced Plastic is coated with a rough material to further enhance the bond between the new concrete filling the void for further strength of the completed pipe structure.

The scope of work encompassed the rehabilitation of approximately 380m of 36″ (914mm) diameter steel water pipeline for the Douglas Rd. Main No. 1 section, from Delta Ave. to Beta Ave. in Burnaby BC. The selected method of rehabilitation was Slip Lining with 30″ (762mm) diameter High Density Polyethylene (HDPE) DR9 pipe with grouting of the annular space between host and carrier pipe. A thick walled pipe (DR9) was necessary to handle the high operating pressure of the GVWD watermain. Residents were afforded the ability to utilize the front entrances to their properties at all times during construction and retain the use of street parking where deemed necessary, highlighting one of the major benefits of trenchless construction – A Less Invasive Process Compared to Traditional Methods.

Eagle Creek Culvert in West Vancouver was experiencing severe failure along culvert invert which could potentially cause above ground failure. The project was determined to be high priority due to close proximity residential properties that had been constructed on the slop directly above ground. PW was able to complete structural rehabilitation works safely, efficiently and cost effectively (at a fraction of the budget anticipated for a traditional open cut method).

During the summer of 2018, PW Trenchless replaced three storm sewer mains in Port Coquitlam. Using Pipe Bursting to install new HDPE pipe, one section was 150 m in length and involved the installation of 16” pipe (400mm) to replace the existing six-decade old concrete pipe.

This burst was located close to a cul-de-sac; it’s path headed east through an easement between four houses, made its way through another cul-de-sac, travelled through another easement through two more houses, and “daylighted” into a large drainage ditch bordering agricultural property.

The staging of the pipe was done on agricultural acreage, and there was no excavation needed for an entrance pit. The exit pit was not deep, and it allowed for the homeowners on either side to access their driveways throughout the preliminary excavation and preparation for the burst.

Once the pulling started, the shallow exit pit did not offer enough support for the pulling rig and the ground started buckling leaving the pulling rig without adequate support. The crew needed some time to come up with a solution that would allow them to complete the burst. Eventually they used steel road plates, inserted vertically, to add the needed base for the pulling rig. Then the 150m of 16”(400mm) HDPE pipe could be pulled through in a matter of hours.

The damage to the driveway, curb and landscaping was quickly repaired, and all connections to service laterals were completed efficiently and promptly. Very little excavation was needed for this project, and less than one truck of asphalt was needed to complete the repaving.

A prime example of the less invasive nature of trenchless construction in action. Intricate work zones accurately positioned throughout densely tree-lined streets allowed for the replacement of deteriorating sewers. Up-sized to exceed current capacity requirements, providing results long into the future, this major construction process was able to be performed while simultaneously preserving not only the trees themselves but even their delicate blossoms.

During the fall of 2017, PW Trenchless replaced AC water mains via Pipe Bursting on the Simon Fraser University Campus adjacent to Terry Fox Field. The existing alignment ran in parallel proximity to the newly laid state-of-the-art running track, any damage caused to this surface would have necessitated the replacement of the whole thing! Pipe bursting removed the need for heavy machinery to excavate along the entire length and therefore mitigated the risk of damage to the track. All track & field activities were permitted to proceed as planned, with the exception of moduloc fencing deployed to protect crews from wayward lacrosse balls, while the target pipe was discretely replaced under feet.

In 2012, a section of trunk sewer pipe that was failing in Richmond needed to be replaced. Because of the close proximity of a block, building conventional well pointing was not advised. We decided to use ground freezing to stabilize the ground to allow the bursting operation to take place. Ground freezing is a common process in New York for building excavation and it is also used in mining and tunnelling. Its use in utility installation is rare. We employed Canadian Dewatering and Wier Jones Engineering to design and install a system of wells, with pipes carrying a recycling coolant driven into the ground using techniques borrowed from the well pointing installation processes.

A refrigeration plant was brought on site and coolant was circulated via a closed looping system. This was done around both manholes, one at each end of the pipe needing replacing. The centre of the frozen zone was excavated down to the pipe, and the pipe burst was accomplished with no danger to the surrounding buildings. There was no movement of groundwater, resulting in no building movement or migration of ground pollutants in this industrial area.

For more information, click here.

The City of New Westminster has been one of the first municipalities in British Columbia to recognize its aging infrastructure. They have assessed all of their underground assets and adopted a more advanced program of pipe rehabilitation than any other city in B C. We have been a part of that program, off and on, for the last 18 years – In fact, we have been part of their pipe replacement program and this is one example of the types of projects we have completed for the city.

Because the city is densifying, the sewage flows have increased dramatically. An example of this is in the area of 6th street, where a number of bursts were completed to rehabilitate an existing sewer main that was not adequate for the quantity of flow. Along with replacing the mains, the new apartments in the vicinity had to be kept online, while the work was progressing. A system of bypass pumps were used to facilitate the sewer outputs from the apartments. Some service laterals were replaced via pipe bursting as well. The project started from a manhole on the very busy 6th Street and progressed North Eastwards for a number of manholes.

A large public pool facility in North Vancouver noticed that its main pool drain line had been corroded because of chlorine and needed replacement. As other methods were not an option, PWT brought its outdoor equipment inside to complete the burst. Rather than removing the entire floor of the pool, a small excavation of 2m X 2m was made at the drain, and a hole was cut in the wall of the pump room, allowing a new HDPE pipe to be installed .

The bursting head was attached to the new HDPE pipe and rods were attached to the pulling head. It was a simple matter to pull the new pipe in, and in the process “burst” the existing failed pipe. The drain needed to be replaced, and the pit to be filled with concrete and tile was only a few square meters in size. The entire floor of the pool would have needed replacing if conventional construction had been used.

An alternate tendering process where the contract is awarded to one entity which comprises both engineering and contracting.

Because PW Trenchless Construction offers such innovative solutions for underground utilities, it is often beneficial for the owner to request solutions based on a performance specification. This allows PW Trenchess to offer unique solutions while working with equally innovative engineering companies. Learn more about design - build here!

More InfoNew installation methodologies include HDD & traditional open cut Learn more about new installation here!

More InfoIn this day & age of pipe systems reaching the end of their projected lifespan, pipe replacement and pipe rehabilitation have become major fields of engineering.

PW Trenchless Construction provides viable options such as pipe bursting, loose fit lining and internal pipe re-construction whether partial & fully circumferential. Learn more about pipe replacement & rehabilitation here!

More InfoThe aging culverts under roads and highways in many case have reached the end of their engineered life-span. We consider the rehabilitation or replacement of these culverts to be vital to our built environment.

PW Trenchless has been a pioneer in working with MOTH, railway companies and municipalities in developing rehabilitation methodologies for the hundreds of thousands of culverts that currently exist in BC. We have offered solutions in both procurement and construction from design-build to sliplining, invert rehabilitation and full circumferential relining. Learn more about culvert rehabilitation here!

More InfoOften pipe failure can be concentrated to one section, for various reason, leaving the rest of the pipe in good condition. The repair of these localized failures are know as external point repairs (EPR's).

EPR's demonstrate PW's ability to work as both a trenchless and civil contractor, completing EPR contracts using our civil contracting skills and assisting other pure trenchless contractors who only have the capacity to work in an existing pipe. Learn more about point repairs here!

More InfoPipe upsizing is the fundamental concept of pipe bursting.

The vast majority of pipes are less than or equal to 200mm in diameter, but with today's densification practices of urban design, there is a major demand to increase current capacity to handle extra flow. Pipe bursting provides the ideal solution to this issue, particularly in an urban setting. Learn more about pipe upsizing here!

More InfoHorizontal Directional Drilling is a low impact Trenchless construction service where pipe is installed in a shallow arc along a bore path which has been created by a drilling rig. Often the terms Horizontal Directional Drilling (HDD) and Directional Boring are used interchangeably, but in our industry we use the word “boring” when we utilize smaller sized drilling rigs with small diameters for short crossings in the hundreds of feet, and we use the word “drilling” when we utilize larger rigs with large diameters for long crossings in the thousands of feet. Learn more about horizontal directional drilling here!

More InfoPrimus Line® is a flexible sliplining solution for the trenchless rehabilitation of pressure pipes. The system consists of a flexible Kevlar® reinforced liner and specially developed end fittings. Primus Line® is not bonded to the host pipe and is self-supporting. An annulus remains between Primus Line® and the host pipe.

Developed by experienced engineers, the system is suitable for different media as well as various application needs and has already proven itself in numerous projects.Learn more about primus lining here!

More Info

When you join PWT, you become part of a community of people who are engaged in the most innovative practices in the Trenchless Industry. We have been instrumental in setting up a scientific method for cities to gain carbon offsets/credits from their use of trenchless construction. This system has been reviewed by the BC Government and has been approved as of December 2018. We expect to see it in common use shortly.

Subscribe to our newsletter for cutting-edge industry updates, expert knowledge, and exclusive content.