Throughout the 1950’s and 60’s the City of Richmond had a program of infilling their ditches with large cast-in-place box culverts. These concrete culverts are in great shape but their joints are failing. Over the years this has caused continuous road surface failures and the city has entertained various solutions to solve the issue. In 2016, a contract was initiated by the City of Richmond specifying that a FRP lining product be installed. PWT, seeing an opportunity to be the frontrunner, bid on this job and was the successful tender. This allowed us to be the first to install GRP in BC in a Sliplining situation.

To complete the process we took a section off the top of one and half sections of the existing box culvert to allow an entry point for new sections of glass-reinforced fibreglass sections of pipe liner. The liner product was custom made in Dubai for this project.

The existing sewer needed to be fully cleaned and prepared by PW Trenchless technicians who all had completed confined space rescue training. Along with the insertion of 330 meters of 2500 mm by 1200 mm pipe, all service connections needed to be reinstalled to the new liner. Upon completion of the liner pipe installation, concrete was pumped into the void between the existing host pipe and the new liner.

Not all Bursts are long sections of pipe needing replacement, and PW Trenchless can easily handle these smaller jobs efficiently.

The section of pipe connecting sewer mains in a Surrey neighbourhood was initially installed in a pipe easement between four house lots. There was no need to upsize, as the flows had been consistent since the area had been developed in the early 1960’s. However the existing pipe that was used was Asbestos Cement. This product can have issues loosing its cement and becoming “mush’ resulting in pipe failure. Pipe Bursting offers a great solution to the replacement of these pipes.

In the case of this particular site, the trees had grown in size along with new installations of concrete walkways, fences and structures, making open cutting this sewer cost prohibitive. To complete this project, a pit on the south side of the property line, straddling two properties, was excavated to be used as the entrance pit. The exit, or pulling pit, was excavated on the boulevard on the northern edge of the road on the north edge of the project. The new pipe was then pulled in and the old pipe “bursted” into the surrounding ground and replaced .

This project was completed quickly, with little to no disruption to the homeowner’s property.

The Highway 99 Oak Street Bridge project is a classic example of our signature process — “The Culvert Way” . For a deep dive click here.

The King George Highway was opened a year after King George’s Royal Visit to Canada in 1939. He planted trees alongside the highway in South Surrey and over time these have become part of the community. When the underlying sewer pipe needed to be replaced, Pipe Bursting was chosen because of concerns over damage to the root structure which would result from choosing open cut pipe replacement processes.

The existing 350 mm pipe was replaced with 650 mm HDPE pipe. This experimental burst did cause some heaving to the grassy area and also to some of the curbs. This was one of the first large upsizes of pipe attempted by PW Trenchless Construction Inc.

Over the years P W Trenchless has rehabilitated over 10 of the large diameter culverts that run under Highway 99 South of the George Massey tunnel. Because these culverts are all multi-plate pipe arches and are exit-controlled type culverts, they tend to fail at the spring lines rather than the invert. This is what had happened in a entrance-controlled culvert. As was the case in most of our culvert projects, we Sliplined this culvert in a slightly smaller pipe arch and grouted the annulus between the 2 pipes. Working in these watercourses means that water and fish control are major issues. We have developed a team of consultants to help with the design, hydraulics, and environmental concerns . Learn more about The Culvert Way.

The District of North Vancouver had a 900mm CSP storm sewer that had been failing for 10 years. Numerous efforts to clean the pipe had resulted in the bedding, surrounding the pipe, migrating into the pipe when cleaning efforts were attempted. The pipe is a critical part of the storm sewer system. The path of the existing pipe passes through polluted ground and is very close to 5 large silos built on concrete slabs. All of these conditions meant that conventional reconstruction was very difficult, and not reconstructing the pipe exposed the city to lawsuits from flooding.

It was decided to reconstruct the pipe using some type of trenchless, and a Request for Proposals was put out for tender. PWT submitted a proposal to Pipe Burst the existing pipe, using a static system, from 900mm CSP to 1050mm HDPE. There were numerous innovative trenchless technologies used to complete this project by the spring of 2014.

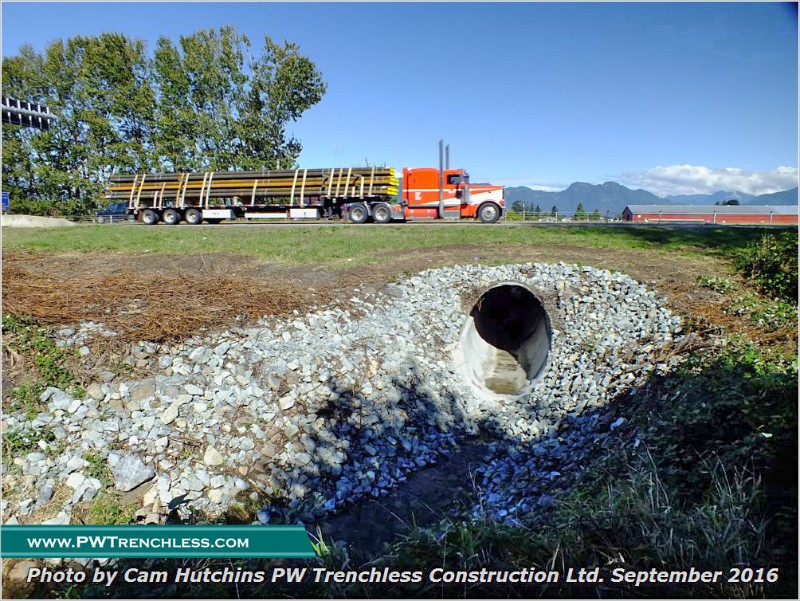

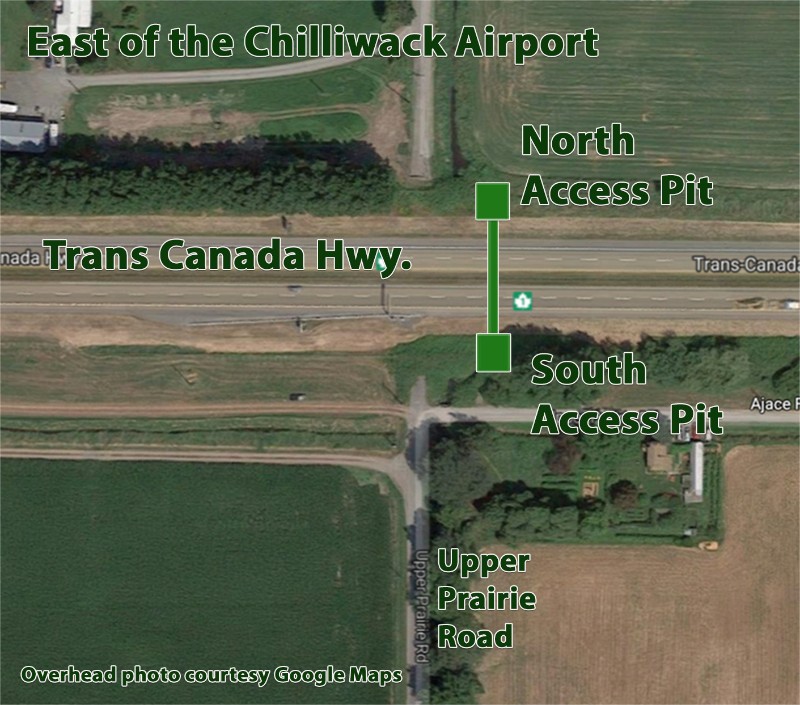

While rehabilitating the Trans Canada Airport Culvert, it was decided to employ a full Sliplining method in order to repair the second culvert. New culvert pipes that are slightly smaller than the existing culvert were delivered to the south end of the project off of Prairie Central Road.

Again a cofferdam and pumping system was set up, and once the cleaning of the pipe was finished, two steel rails were welded in place. The steel rails allowed the new corrugated culvert pipe to be smoothly inserted into the existing corrugated culvert pipe. The rails also allowed for a consistent amount of concrete to be pumped throughout the void to complete the structural integrity of the repair.

The Highways Department had two culverts in need of rehabilitation near the Chilliwack Airport. Both cross under the Highway One Freeway and replacing via Open Cut techniques was not a practical solution.

The first culvert to be repaired was located at Upper Prairie Road and Highway One. The Culvert was only a few metres to the east of the roadway. This Culvert was cleaned and inspected and a repair was decided as opposed to complete Sliplining. The failures were apparent at the bottom 1/3 of the pipe and, with total failure, the top 2/3’s of a culvert can drop and be catastrophic for the Highway.

The decision to use this method allowed for a smaller cofferdam, as full lengths of new culvert pipe were not needed to be lined up and inserted into the existing culvert. The water was diverted using a pump system.

The repair involved welding in place a bed of structural steel rebar and then encase it in concrete. This formed a new “pipe” in the bottom of the existing culvert and was done quickly, and again, with almost no excavation. The lack of excavation around creeks and waterways is very important to preserving a healthy stock of fish, as they need access to the creeks running through the culverts.

PW Trenchless and the City of Victoria engaged in the Rehabilitation of an almost 100 year old Sewer.

Victorian era Victoria B.C. quickly outgrew it’s existing cemetery by the early 1870’s. The City purchased 12 acres from Robert Burnaby Ross Bay Cemetery where it’s first inhabitant, Mary Pearse, was buried in December 1872. Within 50 years, it was already close to capacity, so a new Royal Oak Burial Park was built.

Originally the Ross Bay Cemetery had a few creeks running through it, so storm sewers (1550mm wide x 995mm high) were built to allow for the creeks to be filled in, allowing for more area for graves. The creeks, of course, do not run in straight lines, so the actual sewer is a hand built dual layer of bricks that has many curves and elevation changes.

The cross-section is a half-circle from 9.0 through 12.00 to 3.00 and a gentle V in the invert. It is approximately 1.6m wide and 1.2m high. The alinement also goes through 10 horizontal bends ranging from 5 degrees to 45 degrees, and 4 vertical steps of up to 1m high in the floor. Thus, any liner product had to be brought into the pipe and through these vertical and horizontal transitions. There was no access to the long pipe except at the ends and through one 4m x 2.4m pit in the middle.

This challenging alignment called for a pipe material that could be formed to incorporate a non-circular cross-section, horizontal bends, vertical bends and satisfy structural requirements. Glass Reinforced Plastic (GRP) was the selected material, supplied by Chaneline International. GRP is a precast segmental liner which allows for, after a meticulous measuring process, each section of GRP to be hand formed and specifically designed for a particular location in the host pipe before being shipped to site. GRP can also be designed as a Class I or II liner which assumes either full or partial deterioration of the host pipe.

In early 2017, The City of Maple Ridge put out to tender a contract for an “Experimental” pipe burst in an environmentally sensitive area of Maple Ridge and through part of Kanaka Creek Park. The host pipe was 375mm (15 inch) and it was to be upsized to 850 mm (34 inch).

By the Spring of 2017, PW Trenchless started work on replacing the 375mm PVC sewer main, via Pipe Bursting, that ran through part of Kanaka Creek Park in the City of Maple Ridge. The existing alignment was under a large dense tree line so open cutting here would have been overly destructive. Pipe bursting allowed the intrusion to the green space to be minimized both in terms of large tree removal and native ground disturbance.

The spring of 2017 brought very heavy rainfall and extremely high water levels to Kanaka Creek as it met the Fraser River less than 100m away from the westernmost and lowest manhole. As the water levels rose quickly and unexpectedly PW forces had to react quickly to the changing conditions and reassess their game plan. Rather than expend the resources necessary to effectively dam the site, the decision was made to allow this portion of site to flood and relocate works to the opposite end of the job where there was no danger of flooding, leaving the bursts closer to Kanaka Creek for late July while we waited for water levels to recede. The project was completed over a 5-month period.

We are proud that this project received an Honourable Mention in the No Dig Conference of 2018.

An alternate tendering process where the contract is awarded to one entity which comprises both engineering and contracting.

Because PW Trenchless Construction offers such innovative solutions for underground utilities, it is often beneficial for the owner to request solutions based on a performance specification. This allows PW Trenchess to offer unique solutions while working with equally innovative engineering companies. Learn more about design - build here!

More InfoNew installation methodologies include HDD & traditional open cut Learn more about new installation here!

More InfoIn this day & age of pipe systems reaching the end of their projected lifespan, pipe replacement and pipe rehabilitation have become major fields of engineering.

PW Trenchless Construction provides viable options such as pipe bursting, loose fit lining and internal pipe re-construction whether partial & fully circumferential. Learn more about pipe replacement & rehabilitation here!

More InfoThe aging culverts under roads and highways in many case have reached the end of their engineered life-span. We consider the rehabilitation or replacement of these culverts to be vital to our built environment.

PW Trenchless has been a pioneer in working with MOTH, railway companies and municipalities in developing rehabilitation methodologies for the hundreds of thousands of culverts that currently exist in BC. We have offered solutions in both procurement and construction from design-build to sliplining, invert rehabilitation and full circumferential relining. Learn more about culvert rehabilitation here!

More InfoOften pipe failure can be concentrated to one section, for various reason, leaving the rest of the pipe in good condition. The repair of these localized failures are know as external point repairs (EPR's).

EPR's demonstrate PW's ability to work as both a trenchless and civil contractor, completing EPR contracts using our civil contracting skills and assisting other pure trenchless contractors who only have the capacity to work in an existing pipe. Learn more about point repairs here!

More InfoPipe upsizing is the fundamental concept of pipe bursting.

The vast majority of pipes are less than or equal to 200mm in diameter, but with today's densification practices of urban design, there is a major demand to increase current capacity to handle extra flow. Pipe bursting provides the ideal solution to this issue, particularly in an urban setting. Learn more about pipe upsizing here!

More InfoHorizontal Directional Drilling is a low impact Trenchless construction service where pipe is installed in a shallow arc along a bore path which has been created by a drilling rig. Often the terms Horizontal Directional Drilling (HDD) and Directional Boring are used interchangeably, but in our industry we use the word “boring” when we utilize smaller sized drilling rigs with small diameters for short crossings in the hundreds of feet, and we use the word “drilling” when we utilize larger rigs with large diameters for long crossings in the thousands of feet. Learn more about horizontal directional drilling here!

More InfoPrimus Line® is a flexible sliplining solution for the trenchless rehabilitation of pressure pipes. The system consists of a flexible Kevlar® reinforced liner and specially developed end fittings. Primus Line® is not bonded to the host pipe and is self-supporting. An annulus remains between Primus Line® and the host pipe.

Developed by experienced engineers, the system is suitable for different media as well as various application needs and has already proven itself in numerous projects.Learn more about primus lining here!

More Info

When you join PWT, you become part of a community of people who are engaged in the most innovative practices in the Trenchless Industry. We have been instrumental in setting up a scientific method for cities to gain carbon offsets/credits from their use of trenchless construction. This system has been reviewed by the BC Government and has been approved as of December 2018. We expect to see it in common use shortly.

Subscribe to our newsletter for cutting-edge industry updates, expert knowledge, and exclusive content.