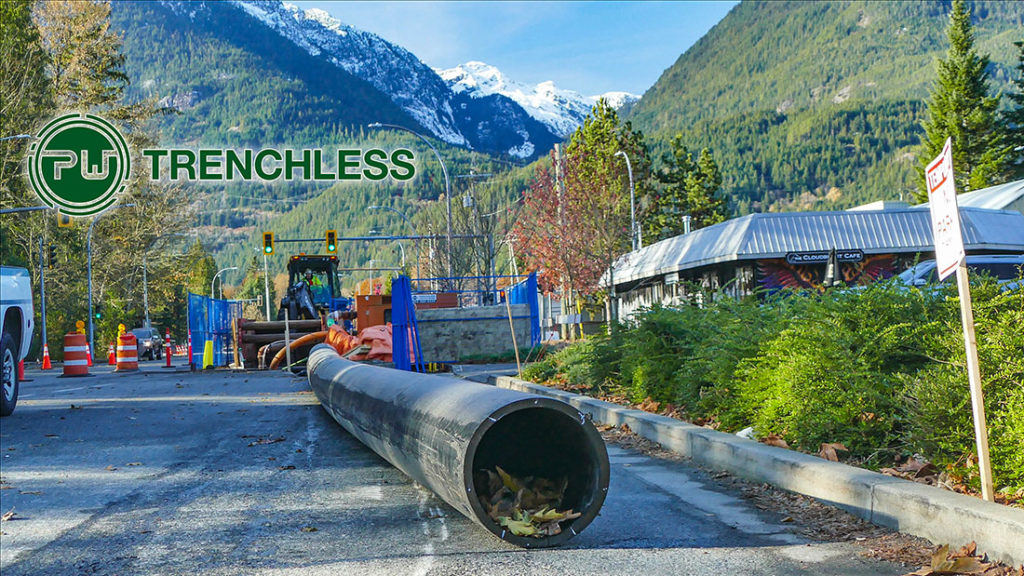

The crew at PW Trenchless were up in Squamish to replace a sewer main under highway 99 via Pipe Bursting. On November 15, 2022, the first burst of 135 metres took place along Mamquam Road towards Highway 99. The exit pit was dug close to the intersection of Mamquam Road and Highway 99.

The site was not suitable for using a pair of trench shoring cages so the removal of the large pipe bursting head was a bit more complicated and required some extra excavation once the burst was completed. The burst went smoothly and the 135m of pipe were inserted via Pipe Bursting in roughly 3.5 hours.

Of course there was quite a bit of set up before the burst was started. For this project, it was decided to excavate around two manholes and jackhammer out the benching and channels of the base of the manholes. This allowed the burst to continue through the two manholes unimpeded, allowing for just one launch of the bursting tool for this 135 metre run. The two manholes had trench shoring cages supporting the excavation as well as a few spots where the existing infrastructure was excavated to make sure the bursting head could pass without causing any problems.

The entrance pit was 4 metres deep so the large diameter 450mm HDPE pipe had to have a long sloped entrance ramp excavated to allow the pipe to enter the host pipe without any grade, allowing the grade of the host pipe to be unaltered.

The HDPE pipe was fused together and there was a large lay down area on the side of the road by the golf course that was not in any vehicles or pedestrians way. There was a bypass pump system put in place and various additional pumps were set up to ensure the excavations were kept dry for the duration of the burst.

On the day prior to the burst, the pulling apparatus was put in place and the pulling rods were inserted into the Host Pipe. The pulling cone was installed on the lead end of the HDPE pipe. The morning of the burst it was moved across the road and put in alignment with the host pipe.

The pumps looked after any existing ground water in the excavations, but luckily it was a dry sunny day. The weather was a bit cold and once the Replacement pipe was staged into the entrance pit it was discovered that the swivel that connects the Bursting head to the pull back rods had a small amount of ice in the cavity. The swivel was hung above the exhaust of one of the nearby generators that were powering the bypass pump and the ice was removed.

Once the head, swivel and pull back rods were attached, the crew took a well deserved coffee break and the burst commenced before 11a.m. The crew was diligent watching the inspection pits to make sure the bursting head and pipe went under the existing infrastructure without damaging any existing pipes.

The site was wide and traffic was only stopped a few times while excavators needed to be moved to align the pull back rods when the swivel and head were attached and then to move a generator to all the vacuum truck better access to remove debris from one of the pits.

The length and depth of this sewer main made it a perfect candidate for pipe bursting, and saved approximately 560 Tonnes of material or 40 truck loads of material from being excavated out of a trench for open cut replacement of this pipe. Unfortunately the section of pipe under the Sea to Sky highway has had some repairs in the past so, pipe bursting that section is still being looked at as a possibility.

In early 2017, The City of Maple Ridge put out to tender a contract for an "Experimental" pipe burst in an environmentally sensitive area of Maple Ridge and through part of Kanaka Creek Park. The host pipe was 375mm (15 …

See ProjectThe District of North Vancouver had a 900mm CSP storm sewer that had been failing for 10 years. Numerous efforts to clean the pipe had resulted in the bedding, surrounding the pipe, migrating into the pipe when cleaning efforts were …

See ProjectDuring the summer of 2018, PW Trenchless replaced three storm sewer mains in Port Coquitlam. Using Pipe Bursting to install new HDPE pipe, one section was 150 m in length and involved the installation of 16” pipe (400mm) to replace …

See ProjectAn alternate tendering process where the contract is awarded to one entity which comprises both engineering and contracting.

Because PW Trenchless Construction offers such innovative solutions for underground utilities, it is often beneficial for the owner to request solutions based on a performance specification. This allows PW Trenchess to offer unique solutions while working with equally innovative engineering companies. Learn more about design - build here!

More InfoNew installation methodologies include HDD & traditional open cut Learn more about new installation here!

More InfoIn this day & age of pipe systems reaching the end of their projected lifespan, pipe replacement and pipe rehabilitation have become major fields of engineering.

PW Trenchless Construction provides viable options such as pipe bursting, loose fit lining and internal pipe re-construction whether partial & fully circumferential. Learn more about pipe replacement & rehabilitation here!

More InfoThe aging culverts under roads and highways in many case have reached the end of their engineered life-span. We consider the rehabilitation or replacement of these culverts to be vital to our built environment.

PW Trenchless has been a pioneer in working with MOTH, railway companies and municipalities in developing rehabilitation methodologies for the hundreds of thousands of culverts that currently exist in BC. We have offered solutions in both procurement and construction from design-build to sliplining, invert rehabilitation and full circumferential relining. Learn more about culvert rehabilitation here!

More InfoOften pipe failure can be concentrated to one section, for various reason, leaving the rest of the pipe in good condition. The repair of these localized failures are know as external point repairs (EPR's).

EPR's demonstrate PW's ability to work as both a trenchless and civil contractor, completing EPR contracts using our civil contracting skills and assisting other pure trenchless contractors who only have the capacity to work in an existing pipe. Learn more about point repairs here!

More InfoPipe upsizing is the fundamental concept of pipe bursting.

The vast majority of pipes are less than or equal to 200mm in diameter, but with today's densification practices of urban design, there is a major demand to increase current capacity to handle extra flow. Pipe bursting provides the ideal solution to this issue, particularly in an urban setting. Learn more about pipe upsizing here!

More InfoHorizontal Directional Drilling is a low impact Trenchless construction service where pipe is installed in a shallow arc along a bore path which has been created by a drilling rig. Often the terms Horizontal Directional Drilling (HDD) and Directional Boring are used interchangeably, but in our industry we use the word “boring” when we utilize smaller sized drilling rigs with small diameters for short crossings in the hundreds of feet, and we use the word “drilling” when we utilize larger rigs with large diameters for long crossings in the thousands of feet. Learn more about horizontal directional drilling here!

More InfoPrimus Line® is a flexible sliplining solution for the trenchless rehabilitation of pressure pipes. The system consists of a flexible Kevlar® reinforced liner and specially developed end fittings. Primus Line® is not bonded to the host pipe and is self-supporting. An annulus remains between Primus Line® and the host pipe.

Developed by experienced engineers, the system is suitable for different media as well as various application needs and has already proven itself in numerous projects.Learn more about primus lining here!

More Info

When you join PWT, you become part of a community of people who are engaged in the most innovative practices in the Trenchless Industry. We have been instrumental in setting up a scientific method for cities to gain carbon offsets/credits from their use of trenchless construction. This system has been reviewed by the BC Government and has been approved as of December 2018. We expect to see it in common use shortly.

Subscribe to our newsletter for cutting-edge industry updates, expert knowledge, and exclusive content.